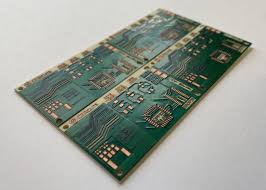

Alumina PCBs

Alumina PCBs are used in a wide variety of applications ranging from aerospace and defense to LED lighting and power electronics. They can withstand high temperatures, mechanical shock, and vibration. They also have excellent thermal and electrical insulation properties. This makes them perfect for demanding environments where other types of circuit boards would fail. But what exactly is an alumina pcb and how are they manufactured?

Aluminum is a very light metal that is often used in circuit boards for its ability to dissipate heat. Unlike other materials, aluminum can easily transfer heat away from vital components in the board, protecting them from damage. This is what allows alumina pcb to handle vibration and shock better than other types of circuit boards.

Besides heat, the aluminum in these circuit boards helps protect them from mechanical and chemical stress. It is this combination of strength and resilience that gives them their unique qualities and makes them a popular choice for many electronic devices.

Website design By BotEap.com

How Do Alumina PCBs Handle Vibration and Shock?

The alumina substrate itself is made from some of the highest purity aluminum oxides available. It is produced to exceed 99% Al2O3 with tight control of trace elemental impurities. The material is then pressed into layers and etched to create conductive paths and interconnects. The resulting board is then passed through a series of inspections and post-firing processes to ensure the proper performance of the circuit.

Once the alumina substrate has been manufactured, it is ready to be used in your application. Viasion has extensive experience in manufacturing and delivering alumina PCBs for a wide variety of industries and electronic devices. We start by creating a design that is tailored to the specific needs of your project. This includes determining the size, shape, and features of your alumina circuit board. Then, we can begin production.

During production, our engineers work with the aluminum core to make sure it will meet all of your requirements. This includes ensuring that it can support the required voltage and current levels, handling the necessary mechanical stresses, and achieving the desired thermal performance.

After all of the manufacturing steps are complete, the alumina circuit board is ready to be soldered. We use our extensive knowledge of different soldering techniques to get the best results. Then, we run rigorous tests to ensure that your alumina circuit board will perform as expected in the real world. When the test passes, your alumina circuit board will be shipped out to you.