Layers in an Assembled Circuit Board

The number of layers in an assembled circuit board is an important consideration for many applications. The more layers a PCB has, the more complex the design and the more functions it can perform. The number of layers in a circuit board depends on the design, which starts with a schematic diagram, a symbolic representation of all circuit components and how they are connected. Once the schematic is completed, it is converted into a layout, which defines the physical dimensions and placement of each component. It also includes the conductive pathways, called traces. The traces connect the different layers of the board and transmit signals from one to another.

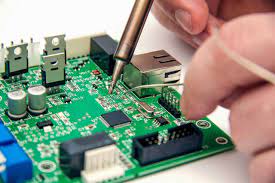

During fabrication, the bare copper foil is laminated to the dielectric composite material using heat and pressure in a process known as lamination. A pattern is then etched onto each layer to create the circuitry. The conductive patterns are then plated with copper to produce the traces and vias that connect the layers of the circuit board. The plated-through holes, which are used to place component leads and connect the external layers of the PCB, are then electroplated with more copper to form the hole walls.

Once the traces and vias are finished, they are covered with a thin layer of solder mask to protect them from contamination during assembly. The top and bottom of the PCB are then silkscreened with the component symbols and a green color that helps identify the parts when they are soldered into position.

Website design By BotEap.com

How Many Layers in an Assembled Circuit Board?

The most basic circuit board has a two-layer stackup, with a brown layer in the center that represents the dielectric and twin grey strips above and below it that represent the copper. The bottom of the PCB is sealed with a green layer of soldermask. This is the most common multilayer stackup for consumer electronics, industrial machines and mobile devices such as smartphones and tablets.

Four-layer boards have more complexity, with a signal and ground plane on each layer. The ground and power planes are typically offset, which reduces electromagnetic interference by minimizing the opposition between the power and signal currents flowing through the traces. These layers are also thicker to provide thermal balancing, which reduces heat generation by transferring the hot components’ conductors down through the ground plane.

For higher-frequency designs, a 12-layer stackup is standard. This provides the additional copper layers needed to handle more signaling and power distribution.

While these higher-layer designs are becoming more standard, they still require careful planning. Routing rules must be followed to ensure that the circuitry can fit within the available space. A continual ground plane is essential, as are separating digital and analog signal paths.